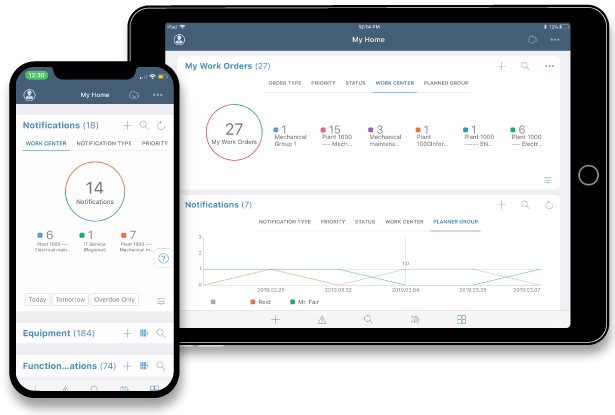

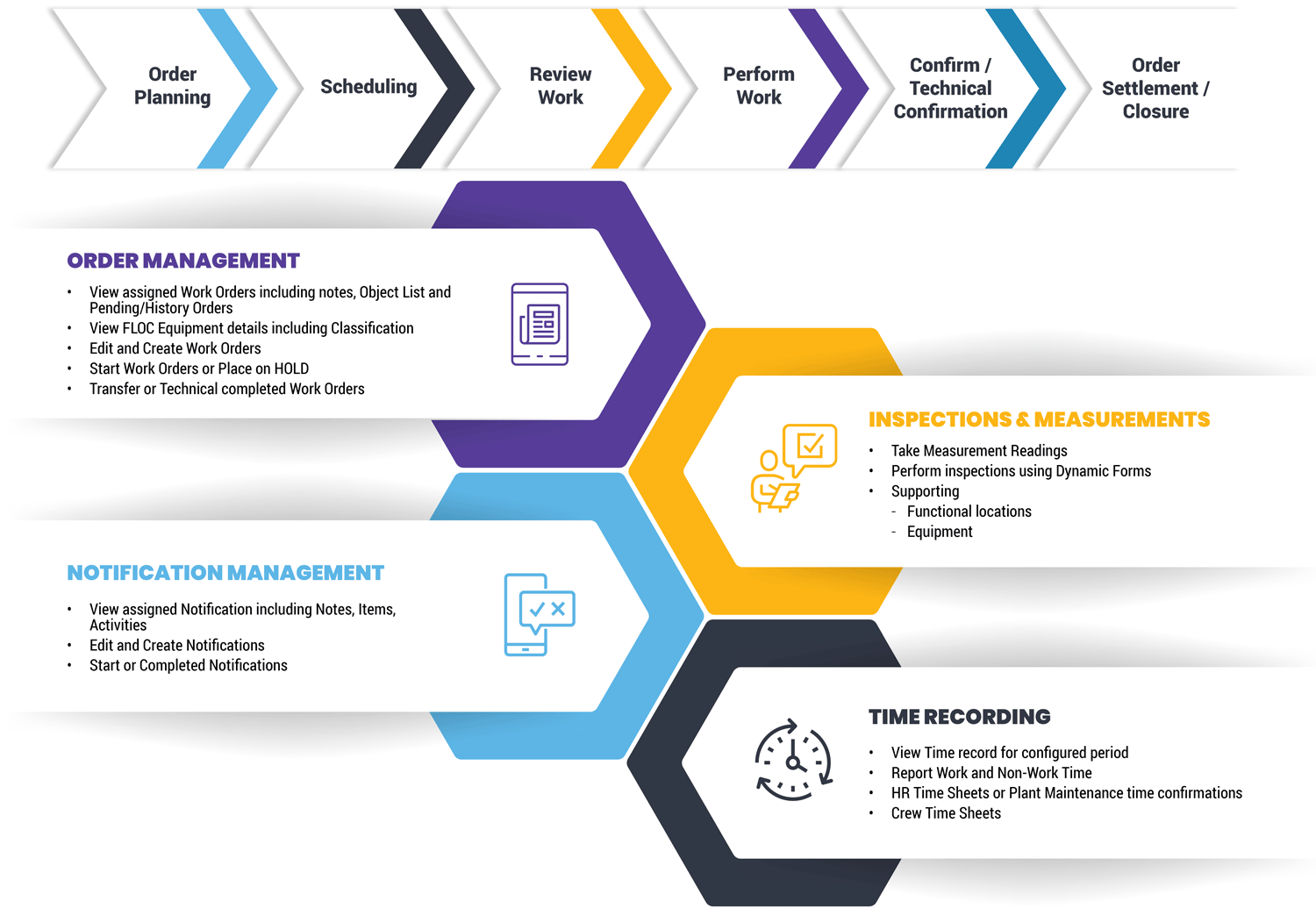

mWorkOrder for SAP PM has been designed to digitize and automate paper based maintenance processes. Starting from mobile work order creation, mobile notifications, mobile work instructions to digital documentation for work order completion, mWorkOrder provides an end to end mobile plant maintenance process flow.

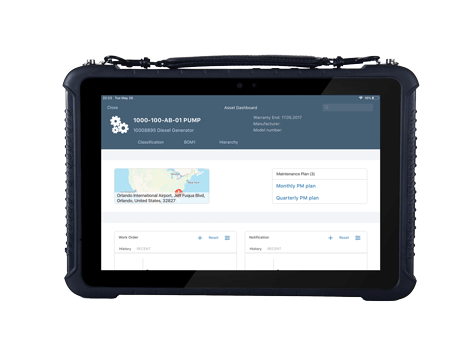

With one scan on your mobile or smart glass device, the Connected Maintenance application auto-detects your machine's complete health & history. Empower your planners, schedulers & technicians with important machine & equipment data at their finger tips. Make smart and intelligent decisions to keep work moving.

Capturing accurate wrench time has been a burning challenge for maintenance managers & executives. The Auto Time Capture feature allows the technician to track time at an operations level.

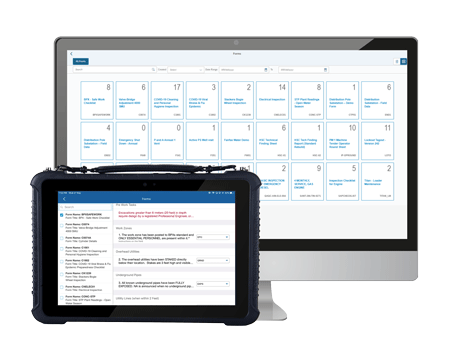

Make use of a digital library of 150+ prepackaged work instructions, inspections, compliance & safety procedures. Use forms as-is or reconfigure as needed, make changes to suit your specific needs & submit in SAP & IBM Maximo Notifications & Work Orders.

Drill down from a functional location into an Equipment Hierarchy and locate a specific Bill of Materials (BOM).

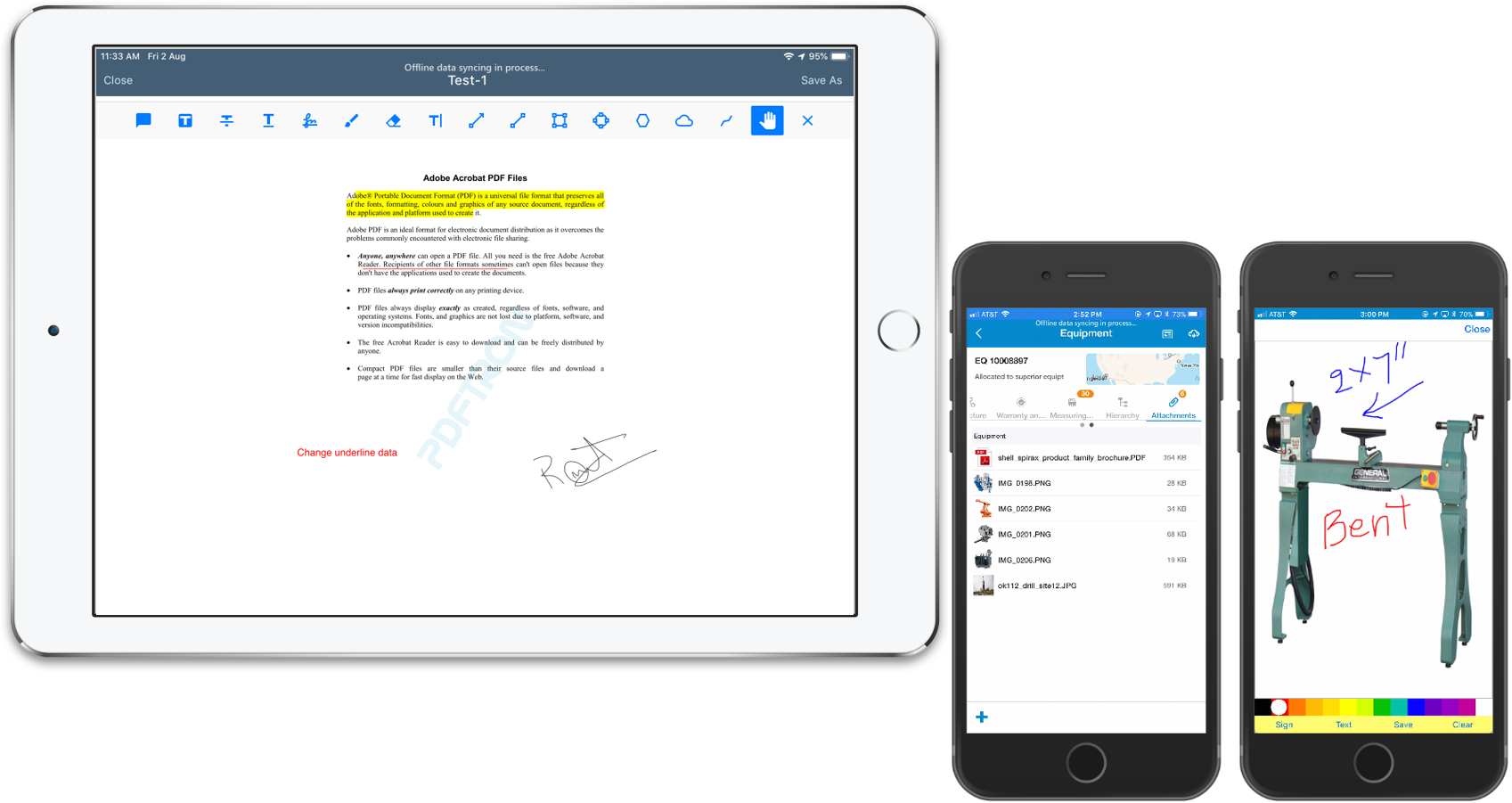

Graphically annotate documents & images attached to Work Orders, Notifications, Equipment, Functional Locations & other maintenance components.

Personalize Connected Worker experiences by user personas, sites, plants & geographies. Simple and easy-to-use personalization helps the Connected Worker get the job done faster, better, cheaper & safer.

Recognizes text & numeric information & digitizes it during the data capture process in a second. No barcode necessary.

-2.png)

Prioritize Maintenance Work Orders based on the Risk Profile of all equipment throughout the facility.

Integrate any GIS - such as ESRI or GE Small World - with SAP and IBM Business Objects (Work Orders, Notifications, Equipment, Functional Location) & guided step-by-step work instructions, inspections & compliance forms.

-Integration-1.gif)

Gain productivity by eliminating paperwork

Standardize work and prevent accidents

Simplify work planning and execution

Eliminate Preventable Failures

Mobile work orders have streamlined our process, reducing time to get paperwork from the field from many days to within minutes. It’s amazing, a great team, great teamwork and a great process improvement using the Innovapptive Connected Maintenance Execution solution. A win for our customers.

Post-Innovapptive, we have dramatically reduced our maintenance backlogs and improved our worker capacity by 12%. This is a direct savings of $10M/year we are experiencing after implementing Innovapptive.

Innovapptive’s Connected Maintenance Execution solution has played a significant role in transforming how we approach maintenance, productivity, data analysis and decision making. We have the solution currently deployed to various locations across Europe and have plans to continue to significantly expand its use. We have experienced a substantial reduction in maintenance backlogs, seen a huge spike in overall productivity and continue to realize operational cost savings due to the visibility and access the solution continues to provide. - Business Manager

By digitizing work orders and automating workflows, mobile Plant Maintenance reduces manual data entry, minimizes errors, and accelerates maintenance processes, leading to increased wrench time and reduced downtime.

Yes, the solution is truly device and platform agnostic, offering full native support on iOS, Android, Windows, and browser access through SAP Fiori launchpad, ensuring flexibility and ease of use across different devices.

Mobile Plant Maintenance offers full offline capabilities, allowing field technicians to continue working without network connectivity. Data is synchronized automatically once connectivity is restored, ensuring seamless operations.