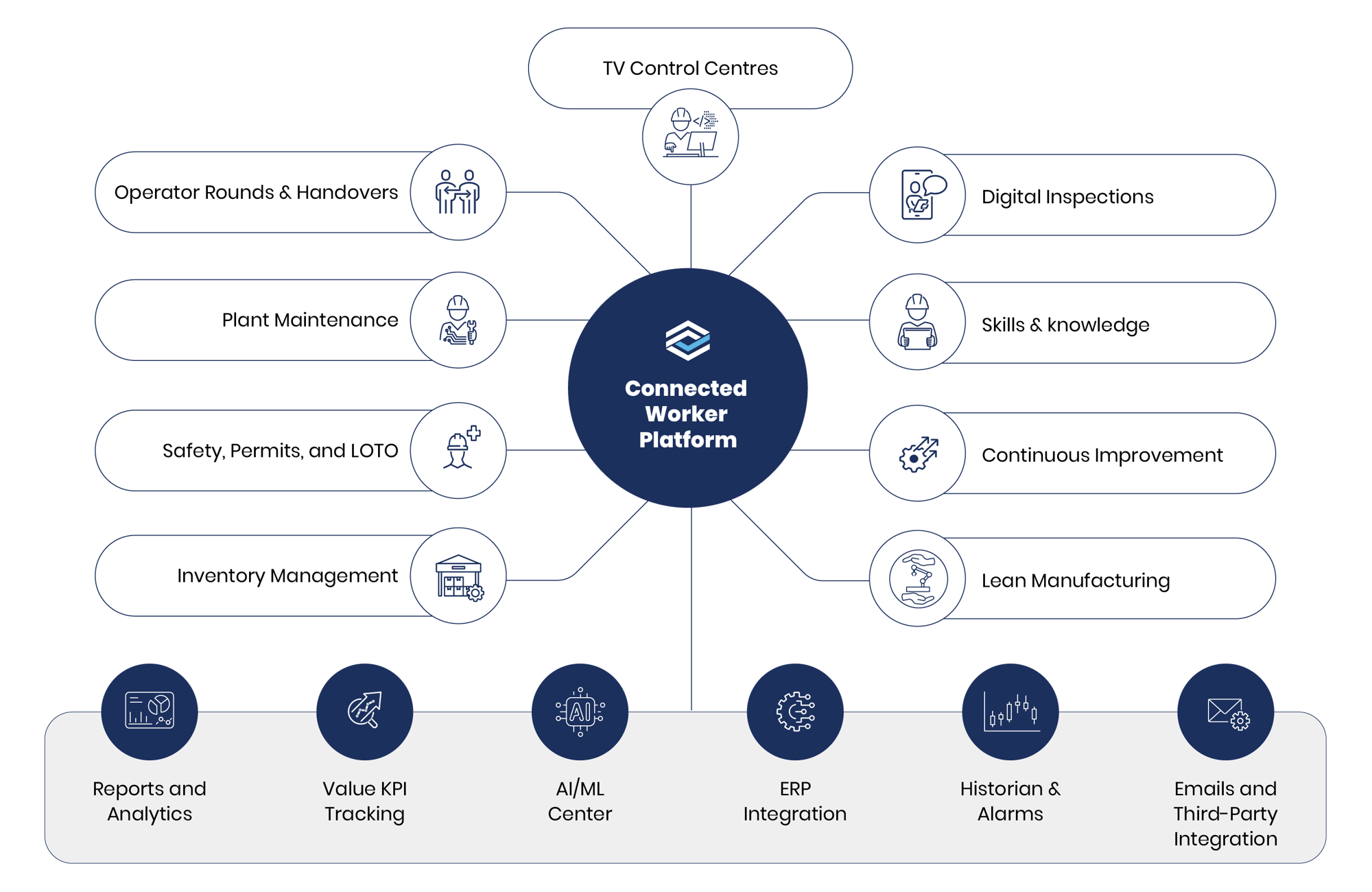

The Proven Connected Worker Platform for Operations and Maintenance workflows

Improve planning accuracy, reduce delays and wasted productivity, real time work queue management and prioritization, ensure better coordination and visibility, onboard and upskill technicians and operators faster.

TRUSTED BY LEADING FRONTLINE WORKERS WORLDWIDE

A Unified Platform Approach to Improve

Productivity, Safety and Uptime

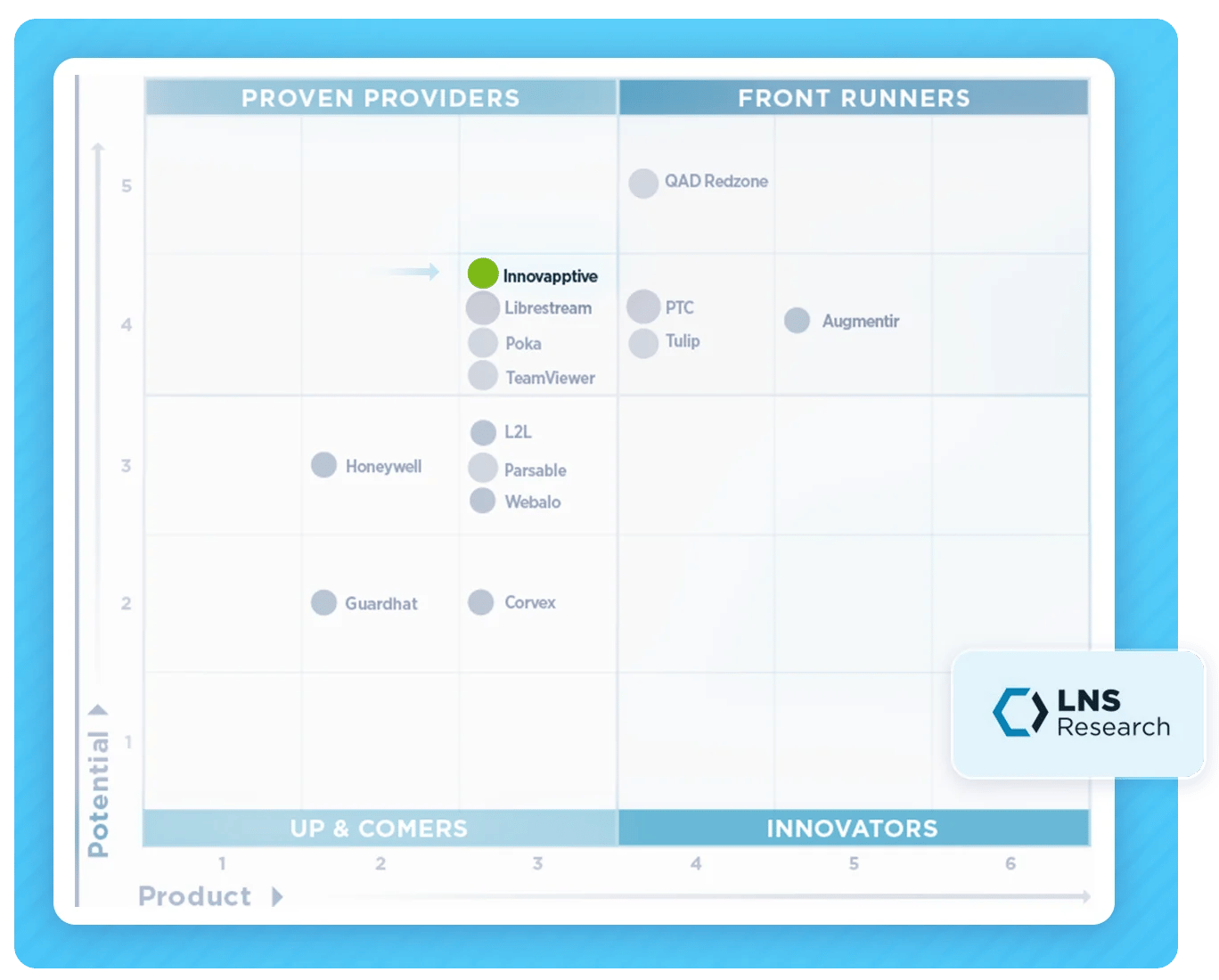

More tools? More Problems. Today's fragmented, point solutions based offerings in the market are a playground for inefficiencies. Distinguished by its robust integrations and persona driven workflows, Innovapptive's Unified Connected Worker Platform Approach has been the cornerstone for companies looking to empower their workforce with seamless, digital solutions to improve productivity and asset uptime. Leverage our deep industry knowledge and comprehensive platform to onboard your workers faster, reduce time to full productivity, and facilitate continuous reskilling and upskilling, all while improving productivity, safety and uptime.

Become a Best Run Business with the Frontline Worker ERP

Tightly integrated with your backend ERP like SAP, IBM Maximo, Oracle etc. Innovapptive's Connected Worker Platform, offers a solution to bring your deskless employees online to perform their duties more effectively and respond swiftly to changing situations. This leads to improved operational efficiency, better resource utilization, and enhanced overall performance of the organization.

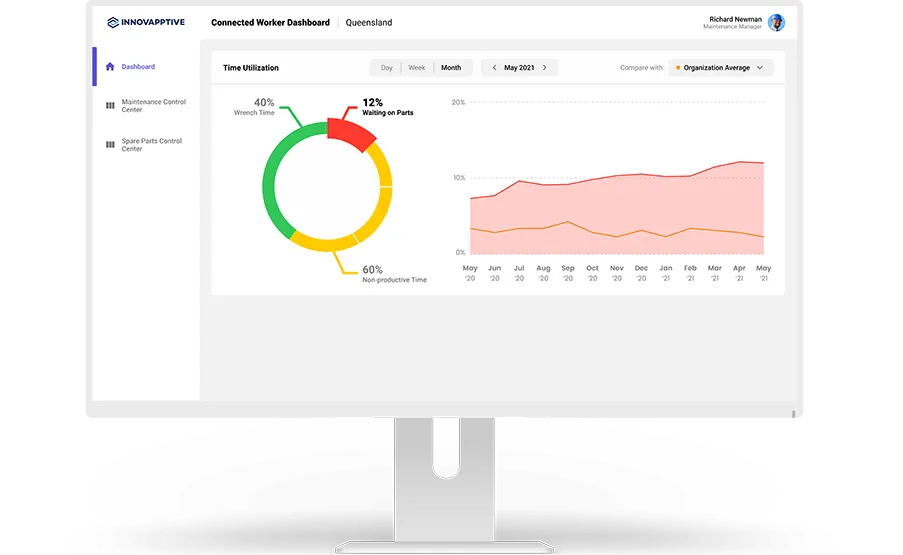

As the most complete AI-Powered connected worker platform that cohesively links operations, maintenance, and warehouse teams with back office decision-makers, we offer a suite that enhances data precision, streamlines communication, and optimizes processes end-to-end. Our platform also stands alone in providing analytics dashboards and control centers that serve as a singular vantage point a comprehensive lookout station from which supervisors can oversee and manage with unprecedented clarity and ease.

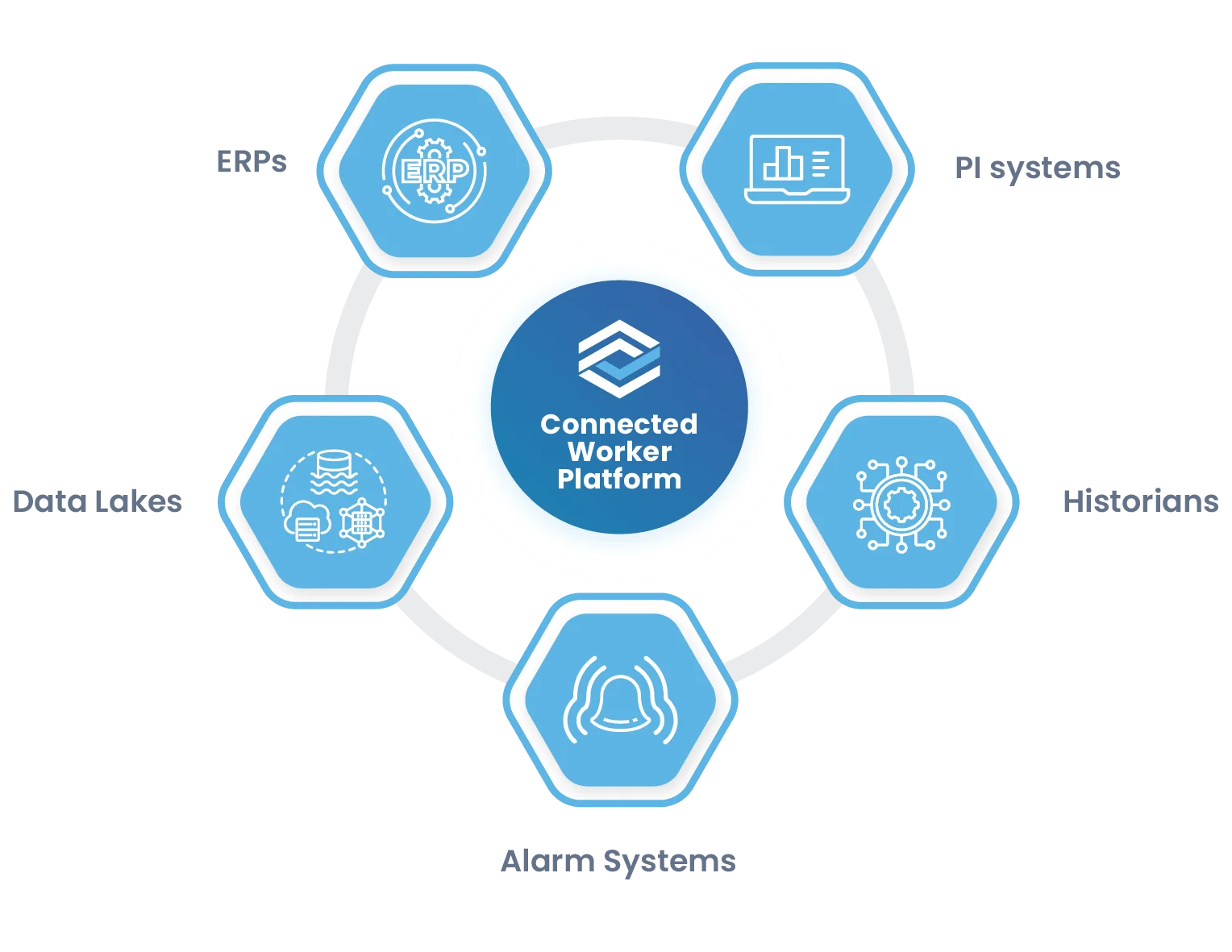

Integrations That Powers Progress

Innovapptive’s platform is the linchpin in an ecosystem of ERPs, data sources, and alarm systems, designed to ensure a harmonious data flow. It embodies the fusion of mobility with AI-driven insights, bringing forth a new paradigm of operational agility and informed decision-making.

More Features

Modernized Frontline Operations

Digitize and accelerate frontline activities, ensuring safety compliance and risk mitigation with concise, actionable data.

Streamlined Maintenance Workflow

Enhance maintenance efficiency with simplified workflows, reducing downtime and facilitating preventive care.

Reliable ERP Integration

Seamlessly sync with ERP systems for real-time, reliable data, maintaining constant operational readiness.

Maximized Plant Uptime

Deploy our tools to boost plant uptime, ensuring consistent production and operational stability.

Inventory Precision

Achieve and maintain up to 99% inventory accuracy, significantly reducing waste and loss.

Empowered Workforce Upskilling

Utilize our platform to skillfully manage workforce development, bridging skill gaps with targeted training.

Strengthened Reliability Matrix

Improve operational reliability with a robust suite of tools, enhancing overall asset performance and longevity.

Quality Assurance

Automate quality control for continuous compliance and swift audit preparation, maintaining the highest standards.

Audit-Ready Systems

Stay ahead with digital solutions that ensure you’re always audit-ready, eliminating compliance concerns.

Platform Overview

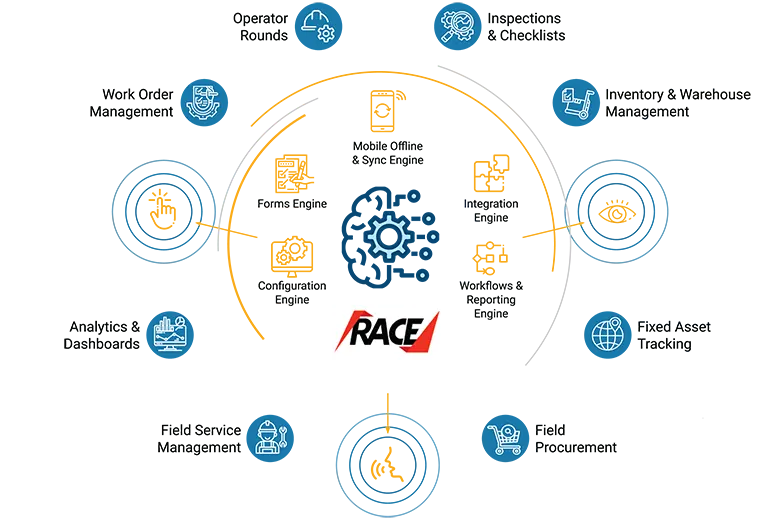

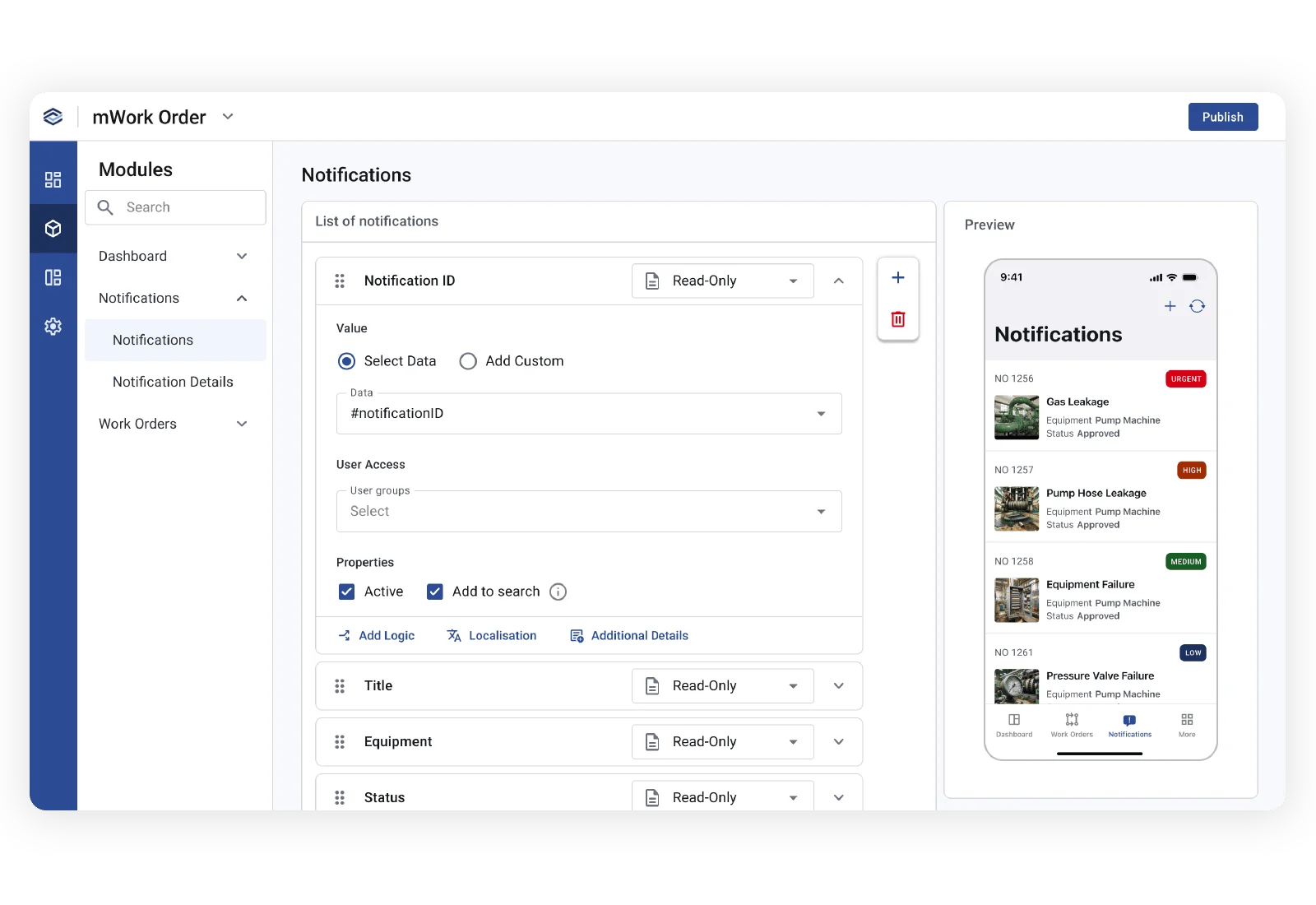

Innovapptive's RACE Technology

At the heart of our platform lies the RACE (Rapid Application Configuration Engine), a patented no-code/low-code platform that enables effortless configuration of apps and ERP workflows. With RACE's WYSIWYG module, users can author forms and rounds within minutes. This backoffice platform also has detailed dashboarding and reporting capabilities enhanced by AI. RACE technology is the backbone of our solutions, significantly reducing total ownership costs by eliminating the need for expensive codebase

Learn More

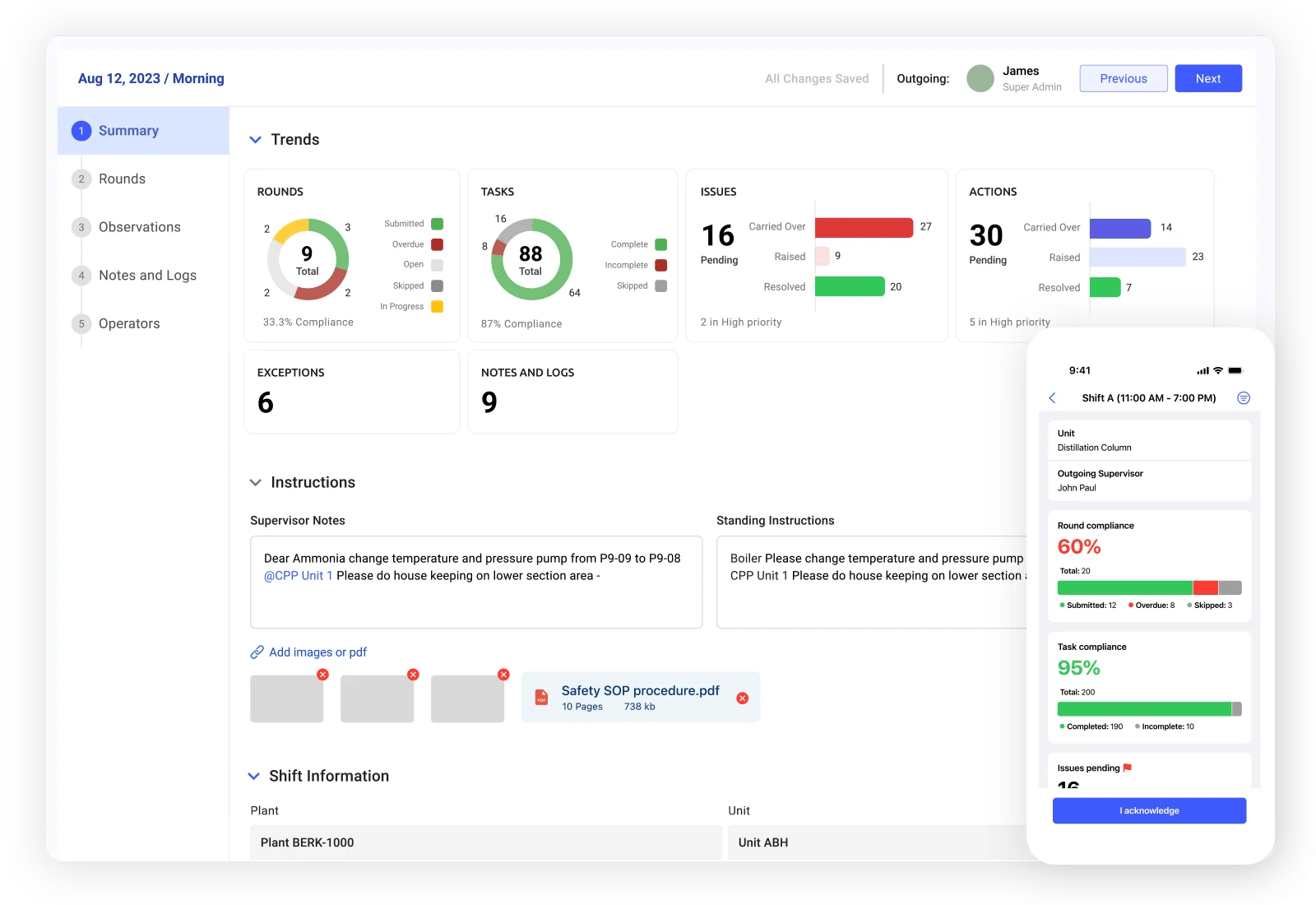

Mobile Operator Rounds

Begin your journey to operational efficiency with mRounds, the industry's leading solution for digital operator rounds. mRounds is the only product offering an automated, dashboard-driven shift handover report, ensuring flawless communication and continuity across shifts. Enjoy benefits such as dynamic round optimization, mobile shift handover reports, and seamless integration with IoT and PI systems for real-time decision-making and efficiency.

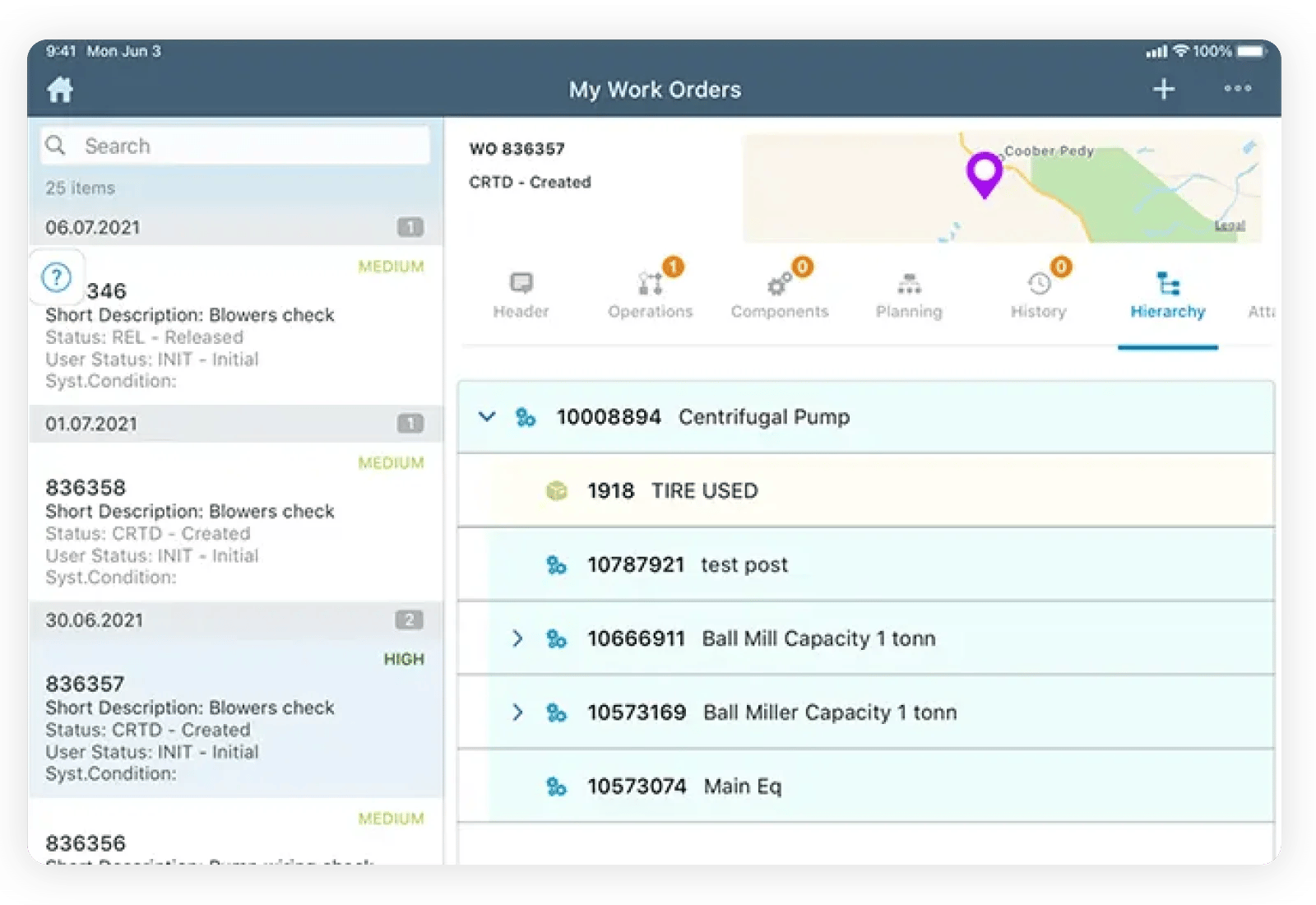

Mobile Work Order Solution

Elevate your maintenance operations with mWorkOrder, a mobile work order management solution that brings no-code/low-code customization, automatic time capture, and a technician-friendly interface to the forefront. With embedded digital forms and step-by-step digital work instructions, mWorkOrder not only improves technician productivity but also ensures precise asset management and reduced downtime.

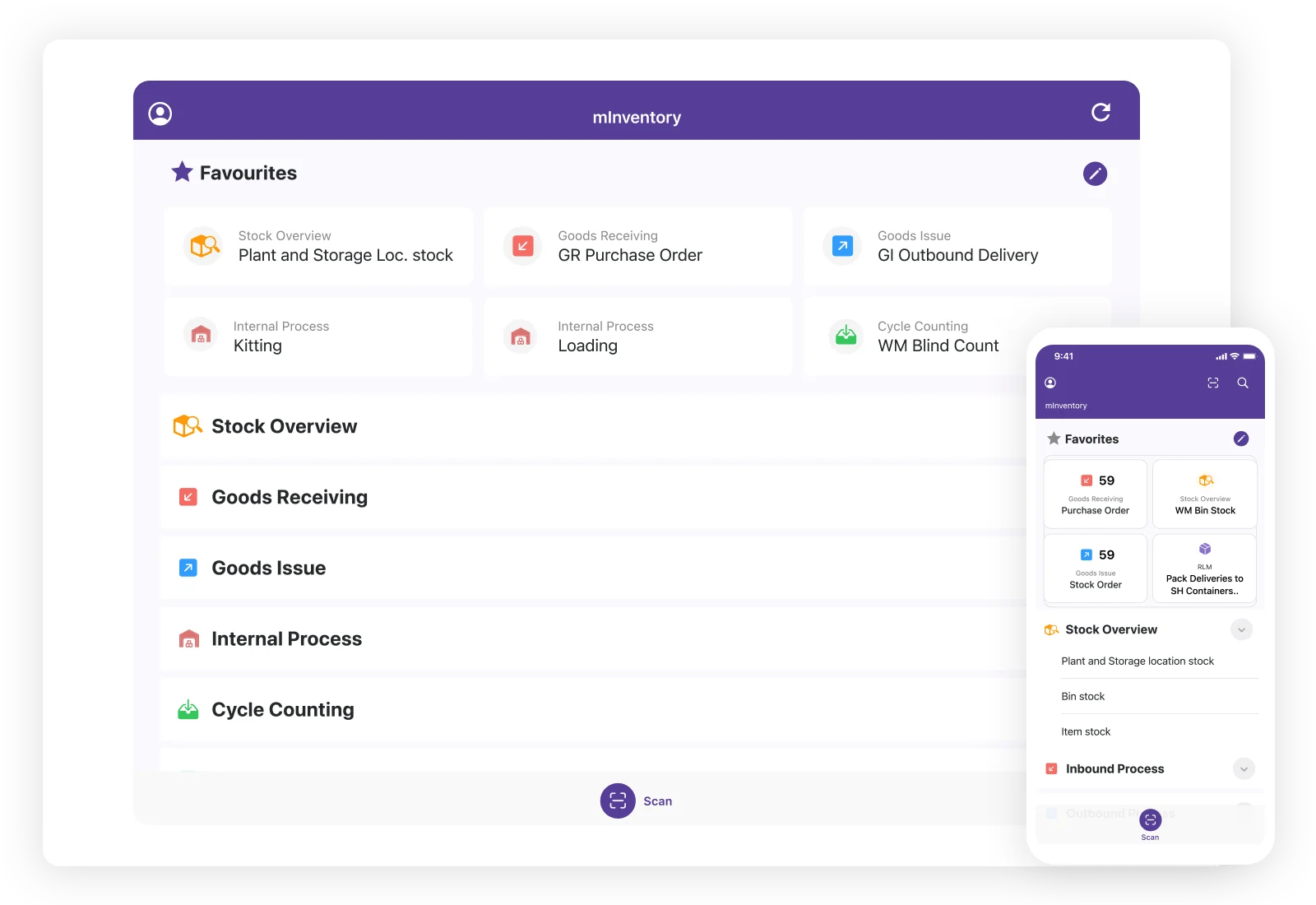

Mobile Warehouse and Inventory Management

Revolutionize your inventory management with mInventory, offering quick and versatile scanning abilities, comprehensive transaction support, and offline capabilities. Integrated with our Rapid Application Configuration Engine (RACE), mInventory allows for flexible workflow adjustments and provides real-time visibility into warehouse operations, boosting productivity and ensuring 99% inventory accuracy.

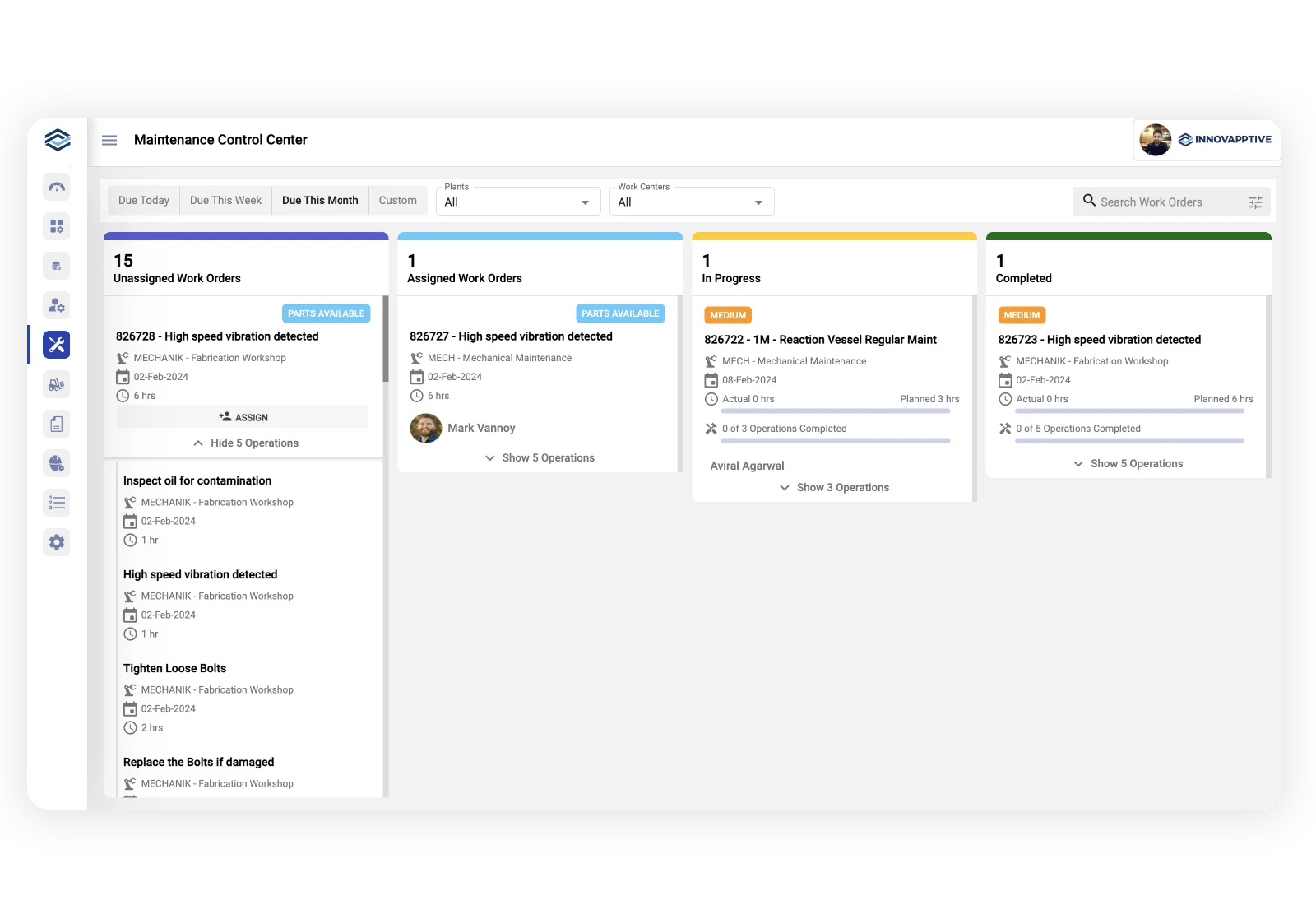

The Control Centre Suite

For back-office supervisors, our suite extends beyond mobile solutions to include comprehensive Control Centres. These platforms enable live tracking of work orders, inventory, and kitting movements, offering an unparalleled overview of your operations. Integrated with an advanced Manager Suite, our solution facilitates connections to additional data sources like historians and alarm systems, ensuring a fully connected, responsive operational environment.

Step into the future today! Request a Demo

More Features

Increasing demand for utility services is putting a greater burden and pressure on electric, water, wastewater, and natural gas distribution asset management programs. Lack of proper asset management can lead to not only more equipment downtime, but a loss of customer satisfaction, higher costs, and increased safety risks.

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe

Warehouse Technician

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to a costly incident

- Ensure production assets remain up and running and workers remain safe