SaaS-Based Mobile Inspections for Greater Industrial Safety

TRUSTED BY LEADING FRONTLINE WORKERS WORLDWIDE

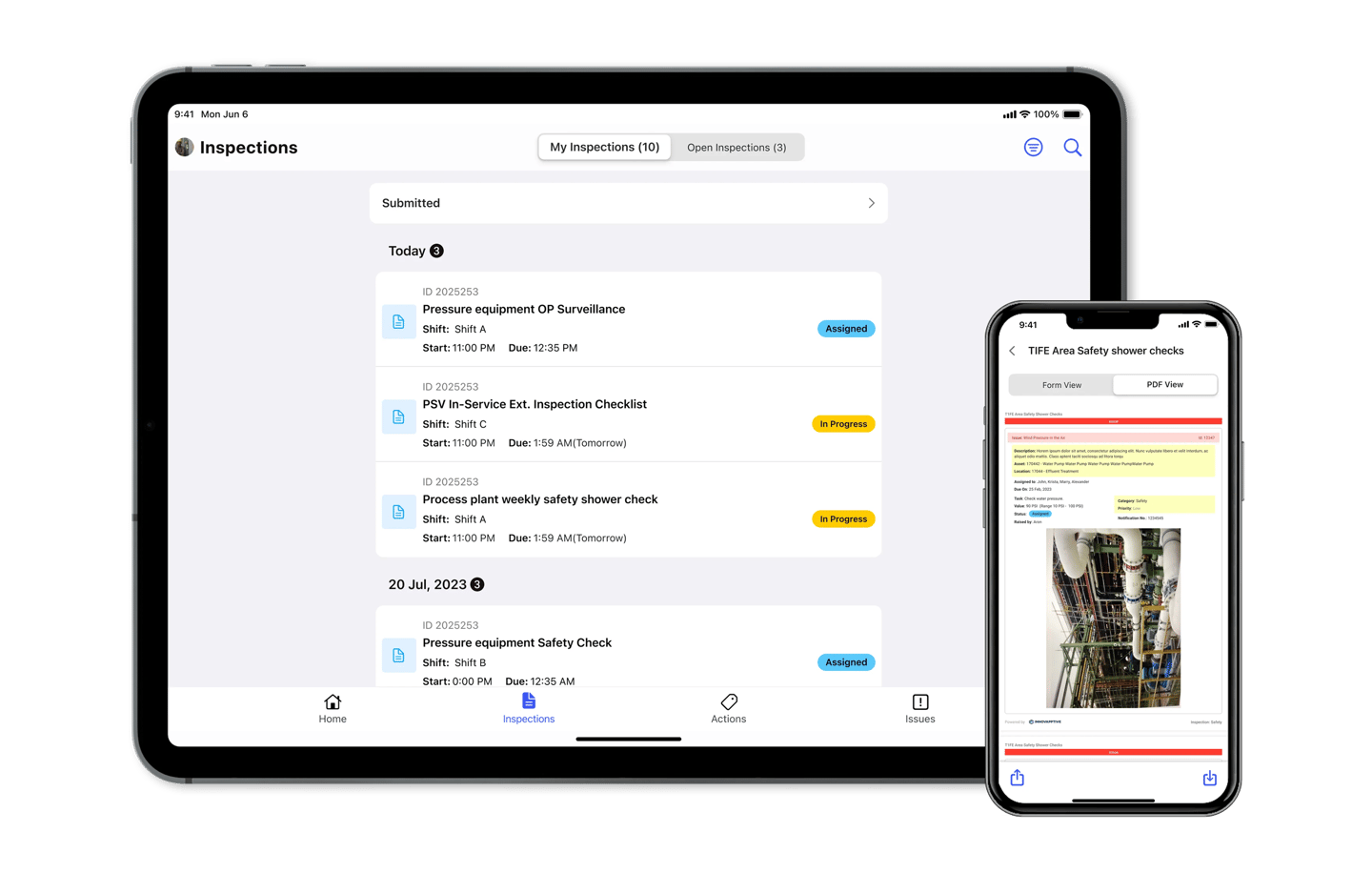

Fast, Accurate Plant Safety Inspections

Make Better Decisions Based on Real-Time Data

- Replace slow, inefficient paper-based inspections with customizable digital forms

- Streamline the inspection process and gain greater compliance visibility enterprise-wide

- Get vital inspection information into decision makers’ hands for quick action

- Make knowledge-based decisions based on real-time dashboards instead of data that could already be outdated

- Improve safety outcomes

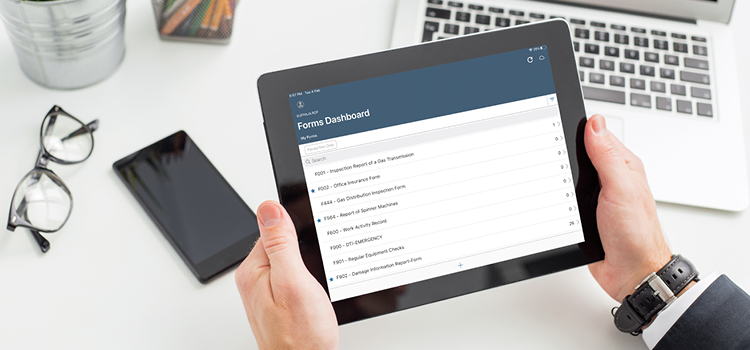

Gather, Store, and Share Safety Inspection Data

Anywhere, Any Time

- Conduct completely digitized inspections

- Complete assigned tasks in the field on any mobile device, including smartphones and tablets

- Automatically upload data into the Cloud at the point of inspection - no manual data entry is required

- Seamlessly work in areas with limited or no Wi-Fi/network connectivity

- Increase productivity and efficiency of inspections

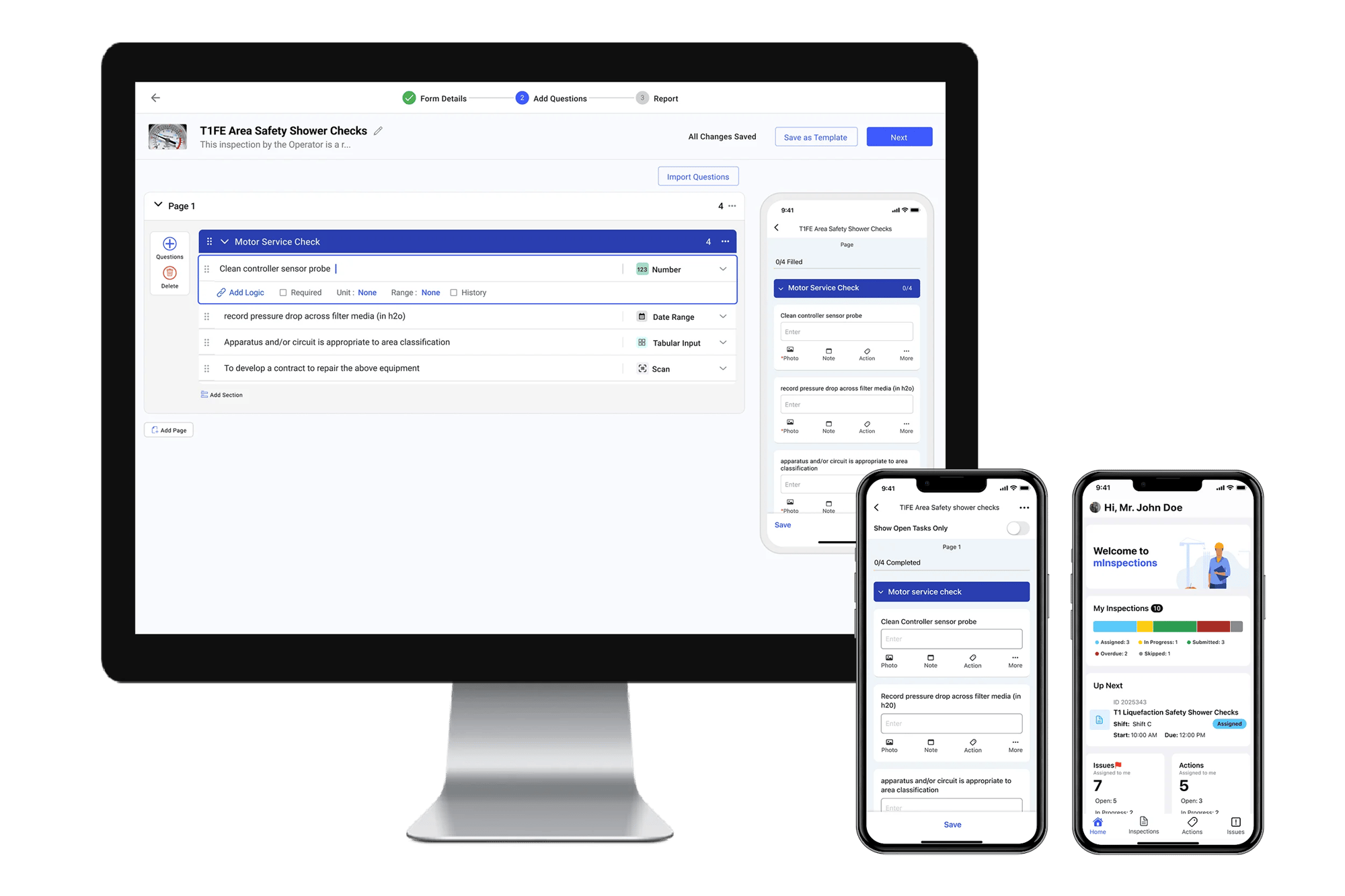

Digitize Safety Checklists in Minutes

No Previous Coding Knowledge or Experience Needed

- Create a digital library of enterprise-wide forms to eliminate paper

- Author, publish, and assign digital inspection forms in 30 minutes or less

- Create customized sections within a form

- Add validations to meet business or site-specific requirements

- Choose from 15+ pre-configured response types

Make Form Changes Yourself On The Fly

No Need to Involve IT

- Quickly implement workflow changes, even if offline

- Ensure forms adhere to changing business conditions and regulatory norms

- Decrease risk, especially during emergencies

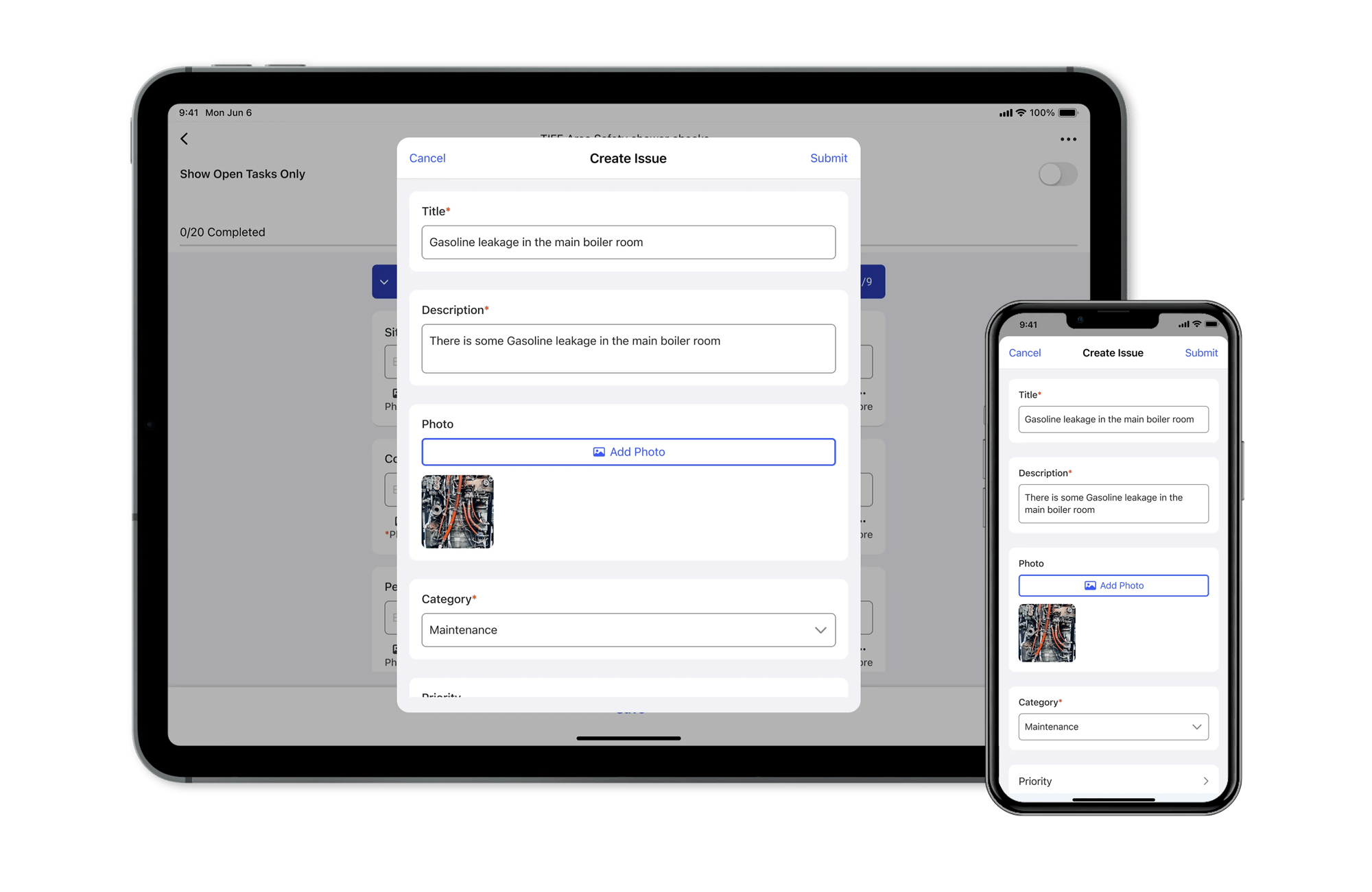

Greater Inspection Accuracy and More-Thorough Data

Ensure Nothing Is Missed With Required Responses

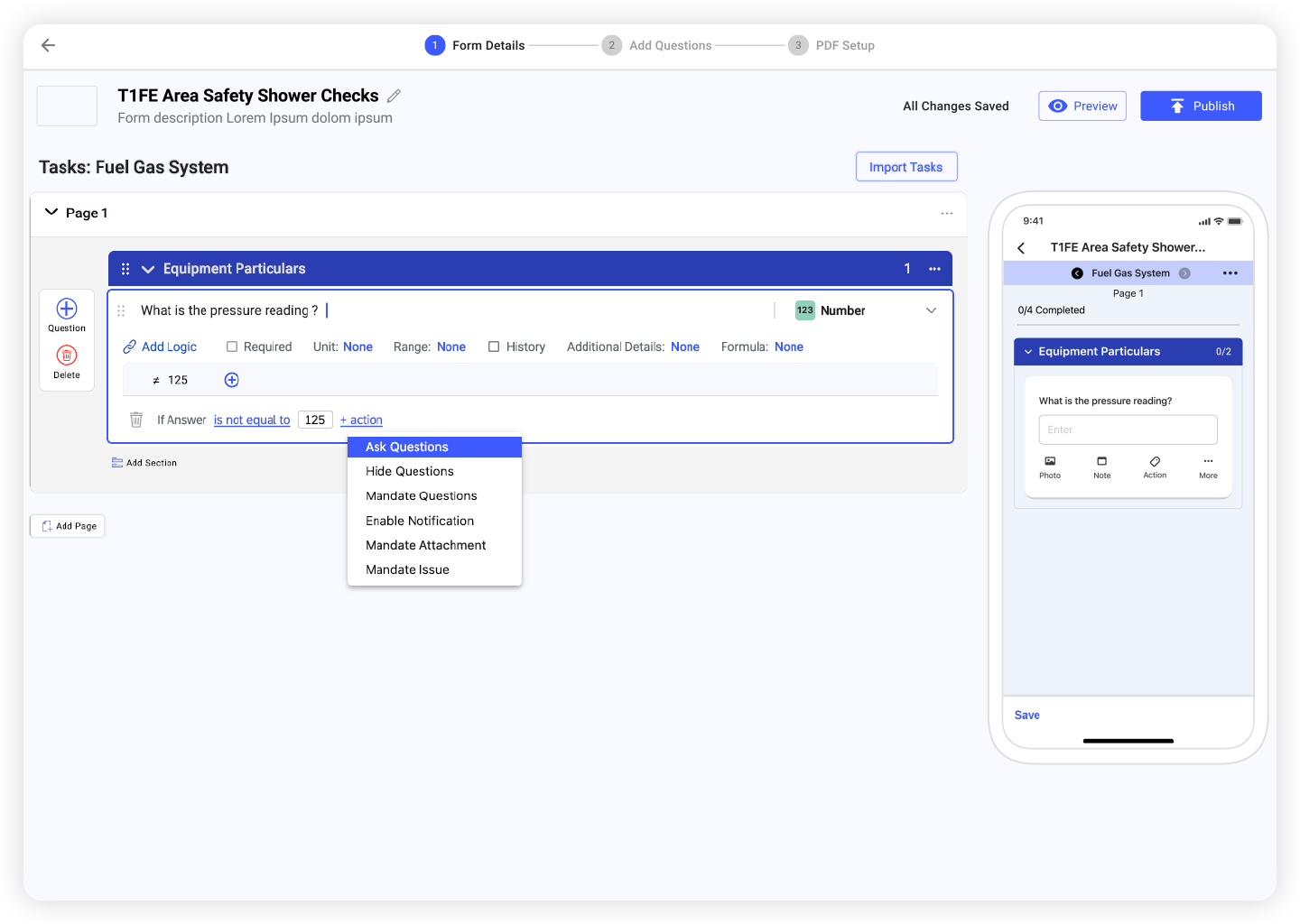

- Create dynamic questions using if/then conditional logic

- Mandate questions that can’t be skipped to complete an inspection

- Link inspections to ERP objects

- Reduce errors and increase data accuracy with user-friendly input options

- Sort and assign inspection tasks so that tasks are performed in a predefined sequence

Why Innovapptive For Your Mobile Inspections

Digitize Inspections Planning

Create detailed inspection plans, assignments, and routes – no paper involved.

Customize Responses

Tailor questions and answers to ensure inspections are completed correctly and accurately.

Set Up Mandatory Fields

Ensure fields can’t be skipped and must be entered before an inspection can end.

Create Dynamic Questions

Use if/then conditional logic to increase accuracy and reduce errors.

Link Inspections to Specific Items

Tie questions and responses to ERP objects.

Sort and Assign Inspection Tasks

Ensure that an inspection is performed in a predefined sequence.

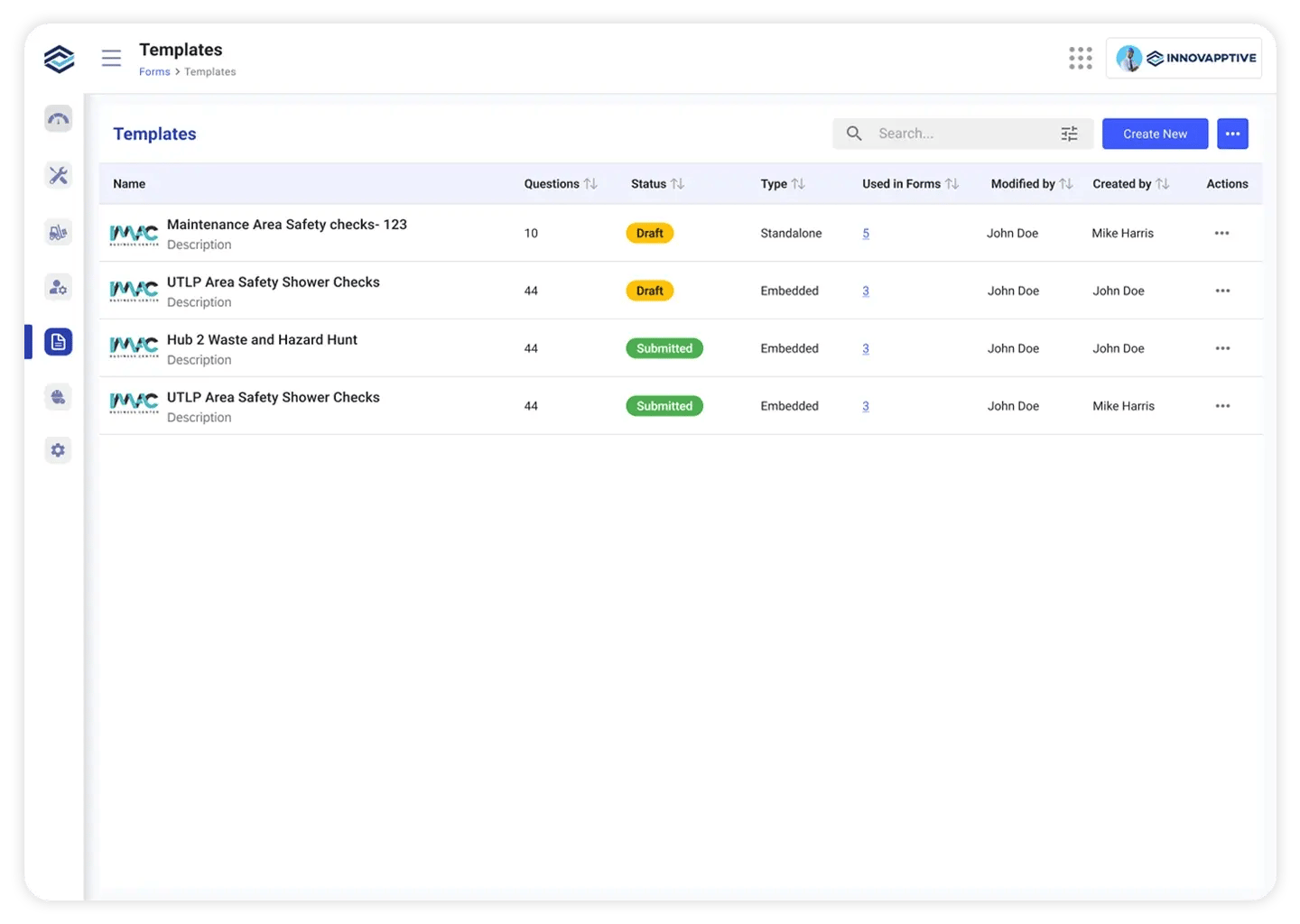

Build Reusable Forms Templates

No need to do the same work twice.

Import Questions from Previous Forms

Import sections and/or questions without having to re-enter them.

Monitor Inspection Progress In Real-Time

Make knowledge-based decisions on remedial action.

Preview Forms Before Issuing

View a form as it will appear to inspectors in the field.

Follow-up Roadmap Reduces Risks

Create notifications and reminders for any completed task.

No Internet Connection? No Problem

Complete tasks offline, then rapidly sync the application when connectivity is re-established.

A Flexible, Agile, and Totally Digital Inspections Process

- Plan, schedule, and issue an inspection from anywhere at any time

- Configure, customize, or change digital inspection forms in 30 minutes or less

- Be productive from the start with intuitive interfaces and simple no-code/low-code technology

- Make more informed decisions and take faster action based on real-time information directly from the field

Is mInspections the

Right Solution for You?

Innovapptive serves industries like oil and gas, chemicals, utilities, mining, and manufacturing. Here is how your organization can leverage mobile inspections.

Oil and Gas

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential safety and compliance issues in the early stages

- Take proactive action before they contribute to costly incidents

- Ensure workers remain safe and regulations followed

Chemicals

- Use at any chemical processing facility, including giant petrochemical plants, agricultural chemicals factories, or process chemical plants

- Accurately monitor safety and compliance situations in real-time

- Gain valuable early warning of potential issues

- Ensure workers remain safe and regulations followed

Mining

- Use in open-pit, surface, subsurface, or in-situ mines

- Spot areas of concern regarding equipment condition or safety

- Take prompt action to resolve the situation before an incident occurs

- Ensure workers remain safe and regulations followed

Utilities

- For use in electric generation, power transmission, natural gas distribution, or water/wastewater facilities

- Gain greater operational visibility into current safety conditions

- Take fast remedial action when a potential issue is spotted

- Reduce incidents and promote a safer workplace

Manufacturing

- Use in any manufacturing plant: assembly, casting, forging, stamping – from automobiles and machinery to durable goods and consumer products

- Understand current operating and reliability conditions in real-time

- Take appropriate actions before an issue causes downtime or a safety problem

- Ensure production assets remain up and running and workers remain safe